Sixty years ago a truck engine oil drain (or oil change) would have been performed as frequently as every 500 miles. Because of higher quality lubricants, cleaner fuels, improved filter technology and more dependable engines, today it is possible to have an oil drain interval as high as 50,000 miles or more on these same types of vehicles.

Nevertheless, typical oil drain intervals remain around 25,000 miles, and little attention is paid to adjusting this standard due to the diverse environments and other factors these vehicles face. For example, two identically produced vehicles may experience a very different oil life; one may reach close to 50,000 miles, while the other might be starving for fresh oil by 15,000 miles. This variance in engine oil life is the result of many factors from three main areas:

- Engine Design, Age and Conditions – Engine design characteristics and numerous running conditions can affect oil life factors from exposures to contaminants and other conditions.

- Driving Patterns and Conditions – Where and how the truck is driven.

- Oil Properties – Quality and formulation performance of the engine oil.

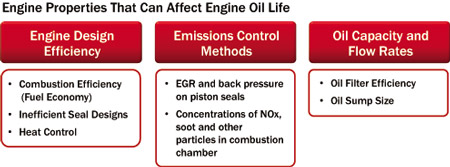

Engine Design, Age and Conditions

Engine fuel efficiency is perhaps the most directly correlated factor to the life of the engine oil. It is improved by combustion efficiency, which can determine the type and amount of particles that are blown by the piston rings. Piston “blowby” is usually the primary source for ingression of contaminants into the oil.

This can include dirt, water, soot, fuel, nitrogen oxide (NOx) and partially burned hydrocarbons (HC). Not only does the combustion efficiency play a role, but other engine design factors such as seal efficiency, temperature control and emissions control methods influence the type and concentration of contaminants in the oil.

Some measureable engine characteristics such as total operating hours and mileage are unavoidable and will likely lead to a shortened oil drain interval. However, maintaining a healthy oil-flow system is manageable by consistently providing sufficient filtration and seals.

In critical components such as filters, the failure mode does not stop with merely a shorter oil life when subpar conditions are experienced. Figure 1 shows how poor filtration can produce a chain reaction of damaging effects on the engine as well as higher operational costs.

Filtration is the counter to contamination. Therefore, it is important that the dirt-holding capacity of the filter be in-line with the anticipated or needed oil drain interval.

In addition to filtration and seals, another engine characteristic that has an effect on oil drain intervals is the oil capacity or sump size. Basically, with an increased volume of engine oil circulating within the engine, there will be a decrease in contamination concentration. Larger sump size also means more oil additives and less thermal distress. As a result, engine manufacturers that offer the largest sump size generally allow for the industry’s longest recommended oil drain interval.

While all engines are designed to provide healthy conditions for the oil to flow, even the best designed models have some level of anticipated contamination over time, either generated from internal or external sources. Consequently, it is the responsibility of the truck owner to ensure that optimal maintenance and healthy conditions are stabilized.

Figure 1

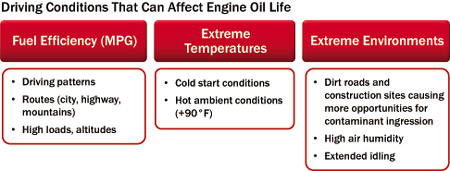

Driving Patterns and Conditions

The conditions an engine oil must endure are reflected in the conditions the truck encounters. Driving in extreme temperatures, for example, is not a healthy environment for the engine oil. On the one hand, cold starts can cause the oil to thicken, which can impair bearing and cylinder wall lubrication at start-up. On the other hand, high heat environments will not only lead to a drop in viscosity but can also result in harmful chemical reactions such as oxidation within the oil and shorten oil life.

Additionally, severe external conditions like dirt roads and high air humidity increase the probability that these airborne contaminants will invade the oil, usually by way of the air intake and through the combustion chamber.

Figure 2

While engine oil has the potential to become contaminated by several external conditions, any factor that influences fuel efficiency also affects the life of the oil. Lower fuel efficiency implies that your engine is not operating at an optimal state, which forces it to work harder. As a result, your engine oil is also working harder. Some of these fuel-efficiency factors include steep roads, high loads, stop-and-go driving, lugging and even the style of driving.

How Times Have Changed

The trucking industry has come a long way in the past 60 years.

1949 Oil Drain Interval: According to its maintenance guide, Gulf had an oil drain interval recommendation between 500 and 1,000 miles.

2012 Oil Drain Interval: Today, the oil drain interval may be as much as 50,000 miles.

Where and how heavy-duty trucks are driven can result in a range of fuel efficiency from 2 to 7.5 miles per gallon (MPG). The MPG number is a useful indicator for determining the engine oil’s duty cycle. Engine manufacturers such as MaxxForce and Cummins have recently decided to recommend an oil drain interval based largely on the vehicle’s fuel-consumption rate.

Figure 3 shows how the oil drain interval for the 2010 MaxxForce engines can range from 18,000 to 40,000 miles. This is significant compared to the previous non-varying recommendation of 25,000 miles, which was the standard guideline for years. Now, not only will better fuel economy save you on gas, but it should also save you on engine oil consumption.

Oil Properties

Diesel engine oils licensed by the American Petroleum Institute (API) and the European Automobile Manufacturers Association (ACEA) are formulated to provide the best engine-protecting properties and to deliver the longest service life possible.

However, even the highest quality oil can be challenged by a range of factors that escalate its own degradation. Not only are the initial conditions (cleanliness, age, etc.) of the engine oil critical but also whether the right performance grade of engine oil is selected to counteract the stressing conditions and exposures that can shorten an oil’s life.

Control of Particles and Other Contaminants

Although one tiny particle might not seem too destructive, it has the power to single handedly generate as many as 20 new particles from the time of ingression to when finally removed, obliterated or settled away. After repeated exposure to particle ingression, contaminated oil may appear to act more like the engine’s deathblow than its lifeblood.

Figure 3. The oil drain interval for some engines can range from 18,000 to 40,000 miles.

In addition, whenever solid contaminants are present within the oil and are not filtered out quickly, the effects can involve more than just the sum of the contaminants themselves. These solids can shorten oil life by combining with other contaminants and conditions. This may include:

-

Sludge and Soot – Formation of sludge deposits through a combination of solid contaminants and moisture results in increased engine wear and shortened oil life.

-

Water and Coolant Ingression – Moisture, glycol and acids promote corrosion, additive depletion and oil oxidation.

-

Fuel Dilution – As fuel becomes diluted, oil films can thin, promoting oil oxidation and loss of viscosity.

Choosing Premium Engine Oils

Premium engine oils, which are typically synthetics, are advertised to improve performance like fuel economy, startability and overall engine cleanliness. However, if the objective is to achieve the best engine protection while being cost-effective, then a premium engine oil is not always the answer. This argument is similar to the decision of whether to buy a hybrid vehicle.

For instance, if a hybrid provides “X” amount of fuel-economy improvements and costs you “Y” more to purchase, it will take you “Z” years before the cost-savings benefit applies. If “Z” is long after you sell the vehicle, you will have lost money. Likewise, premium engine oil provides “X” benefits, costs you “Y” more and will take you “Z” amount of time to reap these benefits. Sometimes “Z” is long after another unforeseen or uncontrollable failure occurs, resulting in a premature oil drain at the very least.

Viscosity and Engine Oil Grades

Since viscosity varies with temperature, it is important that the engine oil maintains a suitable viscosity across the full range of operating temperatures. To achieve this, high molecular-weight additives such as viscosity modifiers (or VI improvers) have thermal-viscosity characteristics that reduce the rate of change.

Figure 4. Whether based on driving, engine or oil conditions, root causes can lead to an increased concentration of oil contamination and produce a shorter oil life and eventual engine failure.

The standard engine oil for heavy-duty trucks has long been 15W-40. At this viscosity grade, the viscosity level is balanced between providing sufficient wear protection while minimizing the energy-robbing viscous drag forces. Nevertheless, if a newer, higher quality engine is used that is less susceptible to internal engine wear, then a lower viscosity engine oil such as 10W-30 or 5W-30 may become a preferred alternative since it will offer improved fuel economy and oil drain intervals.

Figure 4 shows how these root causes, whether they are based on driving, engine or oil conditions, can lead to increased stress and oil contamination, thus producing a shorter oil life and eventual engine failure. Any one of these root causes has the potential to adversely affect the oil drain interval. Keeping the engine oil running smoothly and cleanly is key to increasing the life of the oil and the engine.

The Optimal Oil Drain Interval

The optimal time to change the engine oil is the moment when the damaging effects of the deteriorating oil conditions are more significant than the costs and time saved by extending the interval any further. These damaging effects can be either short term or long term. Short-term effects include the loss in fuel efficiency from the declined condition of the engine oil until the next oil drain. Long-term effects involve permanent damage of internal engine components, which leads to costs related to repairs, rebuilds and downtime.

It can be quite challenging to determine exactly when this ideal moment to change the engine oil occurs. If the condition of the engine oil is known continuously, this moment would be:

-

When the engine oil’s attributes degrade to its condemning limit.

-

When there is a loss of base number (BN) associated with lubricant conditions leading to internal corrosion.

-

When agglomerated soot and sludge begin to form and there is a potential for it to settle or attach on internal engine components.

However, since these conditions are not always known through normal truck operation, the best answer lies with the operator’s ability to monitor the quality of the oil at any given moment either in real time (on-line sensors) or periodically by oil analysis.

Figure 5

Oil Analysis

Although oil analysis can be successful in determining the optimal oil drain interval, it isn’t cheap. For this reason, it is essential that a proper procedure (for both sampling and testing) is performed in order to obtain useful results. Some basic elements that are important to follow include:

-

Optimum and consistent sampling intervals and methods

-

Thorough operating and maintenance records including MPG, oil type, maintenance logs, make-up oil volume, driving patterns, idling time, run time/distance, etc.

-

Optimum test slate and data interpretation strategy

One of the main properties of an engine oil is the ability to neutralize acids. To help improve this ability, engine oil is formulated with alkaline additives (typically detergents). This alkalinity, which can be measured as the BN, provides a good evaluation of an important aging property of the oil. This is because the BN will drop as the oil begins to oxidize or become excessively contaminated with glycol or acidic combustion blowby.

Just as fuel efficiency may be the single most influential factor that decreases oil life, BN is perhaps the single most reliable direct measure of engine oil degradation. Other important factors include soot load, soot dispersancy, contamination and additive depletion.

Operator and Fleet Owner Estimations

When estimating the optimal oil drain interval, fleet owners and owner-operators have different challenges and advantages. Fleet owners can utilize a large number of data from common routes to develop truck-based and route-based trend analysis, which can be very reliable. Owner-operators of trucks driven solely by one or two people can make reasonable estimations due to the driver’s understanding of the vehicle’s tendencies and operating history.

The operator’s ability to monitor the driving style, operating environment (e.g., climate, ambient dust and terrain), selected engine oil and filter, engine efficiency, etc., can also help achieve the optimal oil drain interval.

Figure 6

Symptomatic Diagnoses

The health of the engine oil is critical to the health of the engine and the vehicle as a whole. In many ways, the engine oil in a vehicle can be compared to circulating blood in the human body. For example, engine oil is circulated throughout various engine components to provide wear protection that keeps the engine functioning properly, helps maintain a good engine temperature, cleans out contamination, and contains characteristics that inhibit corrosion and improve sealing.

Likewise, the blood in a human body is circulated throughout various organs to provide nutrients that keep the body functioning properly, helps maintain a good body temperature, cleans out metabolic waste, and contains characteristics that inhibit infectious diseases, bacteria and parasites. Engine oil is filtered by an oil filter, and blood is filtered by organs such as the spleen and liver.

Blood is useful not only because of what it provides the body but also because of what it can indicate about the condition of the body. When a patient goes to the doctor with an unknown illness, the doctor will first try to determine the cause by using the known symptoms. If this is not enough, a blood sample can be taken and examined in a lab. The blood acts as a signature of the body as a whole, offering additional clues as to the cause of the illness.

Figure 7

Engine oil provides this same kind of signature for the engine and all the components through which it flows. An engine may have observational symptoms of how well it is operating, but sometimes these are not enough to indicate engine failure. If an oil sample is taken and examined in a lab, the particles found can offer clues that could predict failure long before any signs are observed.

While understanding the condition of the engine oil in order to detect clues of an engine failure is important, the changing condition of the oil is also a means of failure. To identify the optimal oil drain interval, consider all the factors and symptoms.

Increasingly, vehicle manufacturers, including heavy-duty truck manufacturers, offer in-dash indicators to alert the driver when the engine oil needs to be changed. However, many of these are based solely on a single factor, such as mileage or engine hours, to assist the driver with when the oil was last changed. In some higher end vehicles, more sophisticated methods are utilized, including direct measurements, algorithm methods or a combination of the two.

Direct measurements may employ a variety of onboard sensors through electric capacitance or a micromechanical resonator, which can detect and roughly measure the amount of contaminants in the oil. Algorithmic methods use several variables provided by the engine’s control module, including oil temperature change, oil level, miles per gallon and average miles per hour.

| 41% | of lubrication professionals consider where and how a vehicle is driven as the most influential factor on the life of the engine oil, based on a recent survey at machinerylubrication.com |

Figure 6 demonstrates how just two measurements (miles per gallon and average miles per hour) influence the oil drain interval. If a calibrated map similar to this was formulated with an algorithm incorporating all the engine oil factors mentioned previously, a more reliable method of pinpointing the right time for an oil change could be determined.

The best part about this method is that all the information can already be supplied by the engine’s control module. If onboard sensors were included to provide more information about the contamination levels in the oil, then the reliability of this method could be expected to increase considerably.

In summary, the end of oil life is influenced by a complex array of factors. Many of these can be monitored, controlled and used to optimize the oil drain interval. These include driving patterns, oil analysis, algorithms, onboard sensors or any of the other methods previously described. Furthermore, the benefits extend far beyond keeping the oil clean. Contamination in engine oil is damaging to the engine’s operation, but it can also provide clues to subpar engine operation, premature engine failure and less than optimal oil life.