How to Achieve Gear Coupling Reliability

Tags: gear lubrication, greases, maintenance and reliability

Gear couplings are among the most commonly used methods for connecting process equipment. When properly selected, installed and maintained, they can provide long life and good reliability.

Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density.

However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. Often these failures begin because of a lack of knowledge or a lack of execution of certain fundamentals, which are necessary for these couplings to run reliably.

Design, Selection and Sizing

Selecting the correct coupling for the application is critical for gear coupling reliability. Use the following steps to help make the selection process easier:

-

Choose the coupling style and design (Fast’s, Series H or Waldron; flex and rigid halves; close coupled or floating shaft; gear teeth specifications and misalignment requirements).

-

Select the service factor (SF) from the original equipment manufacturer’s (OEM) gear coupling charts. Shock loads or variable loading can cause premature failure if adequate SF is not used. Typical service factors are in the 1.5 to 2.0 range. Some manufacturers may even specify a misalignment factor for gear coupling sizing when higher coupling misalignment is expected.

-

Calculate application torque (T) requirements based on design brake horsepower (BHP), SF and speed.

-

Choose a coupling with a torque capacity greater than the torque requirements. Since the service factor is already factored in, there is no reason to add additional capacity.

-

Confirm that the coupling selected has a bore capacity greater than the actual application bore (shaft size). Frequently the maximum bore size will drive the coupling sizing process and even increase the coupling torque capacity two to three times what was previously calculated.

-

Verify the shaft depth available for the coupling hub and compare to the actual hub depth. If the hub is too long, it must be either overhung or machined off. Since the hub to shaft engagement is the same in either method, it is preferred to have the hub machined off due to torsional effects of the overhung hub. If the hub is overhung or cut off, further examination may be necessary to determine if there is enough torque transmission capacity available. The rule of thumb is a 1-to-1 ratio for the hub length to the bore.

-

Check a dynamic balance chart to see if the coupling needs to be balanced. High-speed gear couplings may require balancing.

-

Ensure the coupling will fit around the equipment and guarding. This is typically something that can become an issue when there is a design modification on existing equipment. Guards that allow maintainability will encourage proper maintenance in the long run.

Installation

Some couplings don’t get much of a chance at a decent life due to their installation. Just like other components that experience infant mortality, often times these parts don’t die but are murdered. Certain elements of gear coupling installation must be considered if optimum reliability is to be obtained, including:

-

Hub and Sleeve Fits - Determine the type of hub fit (clearance, locational or interference). Higher speed applications should have an adequate interference fit to offset centrifugal force effects on shaft/hub contact pressures. Excessive hub interference fits can lead to hub cracks and hub failure.

-

Keys and Keyway Fits - Keyways should have a proper radius to reduce the risk for fatigue cracking. Key lengths should be measured to minimize the coupling imbalance.

-

Hub Bore - Ensure the hub bore is concentric to minimize hub runout.

-

Hub Installation - Choose proper heating methods so hub material properties are not compromised and select the proper heating magnitude for interference fit hubs so the hub slides easily on the shaft. Never use a hammer to install or remove hubs, as this can cause bearing damage.

-

Correct Coupling Gaps - If floating shafts have a small coupling gap, the shafts may impact one another under misalignment as the shaft oscillates during operation.

-

Proper Sealing - Always use proper gaskets and O-rings so the lubricant stays in the coupling.

-

Alignment - Install the coupling so misalignment stays within manufacturer limits with respect to offset, angular and axial misalignment.

-

Fastener Assembly - Choose the correct type of fasteners (fine or coarse, length, exposed, shrouded, etc.) and the proper arrangement. While standard bolts can work, they may put the threads in the shear plane. Coupling bolts need the correct preload, which is accomplished by proper bolt torque methods.

-

Lubrication - Get the right product in the right amount at the right time for optimum gear coupling reliability.

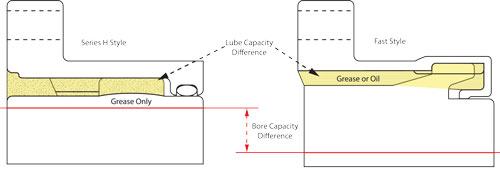

Different coupling styles have different lube and bore capacities. (Ref. Kopflex)

Lubrication

Perhaps the most important operating factor for a gear coupling to be reliable is lubrication. Selection of the proper lubricant is the first step. Many coupling manufacturers supply their own lubricants for their couplings.

Gear couplings may either be grease- or oil-lubricated depending on the design. Oil-lubricated couplings will not dry out like grease couplings, while Fast-style couplings have smaller bore capacities.

It is fair to say that most gear couplings are grease-lubricated. Coupling greases have special properties, so general-purpose greases should never be used in gear coupling applications.

Gear couplings can be subjected to very high centrifugal forces, and oil separation is a critical element of coupling greases. Since greases are comprised of oil and mostly a thickener, special considerations must be made regarding the selection and application of coupling greases.

Soap thickeners typically are heavier than the oils, so centrifugal forces tend to deposit the thickener at the gear teeth. Generally, a grease with a high oil content of high-viscosity oil and a grade 1 rating from the National Lubricating Grease Institute (NLGI) is preferred.

A higher consistency grease may be considered for high-speed applications but should be avoided at low-speed applications.

Grease specifications may include speed limits or certain tests such as the K36 separation factor. Any grease will have oil separation based on time, temperature and centrifugal force.

The K36 factor determines the maximum oil separation of the grease while running at 36,000 Gs. A K36 factor of 8/24 means the oil separation was 8 percent in 24 hours. In comparison, a grease with a K36 factor of 3/24 would mean that it did not separate as much as the grease with a K36 factor of 8/24.

Higher oil separation is desirable at lower speeds (lower G forces), while lower oil separation is preferred at higher speeds and higher temperatures. High-vibration equipment can also enhance oil separation and induce failures. Studies have even shown that gear coupling wear rates decrease as coupling speeds increase.

The main function of a lubricant in a gear coupling is to reduce the friction between the gear teeth as they slide against each other. The relative motion between the mating gear teeth occurs in the axial direction due to slight shaft misalignment. This motion is oscillatory, low amplitude, relatively high frequency and a function of the magnitude of angular misalignment.

This sliding axial motion between the gear teeth can generate lots of wear if lubrication is not sufficient. This is why the gear coupling lubricant plays such a critical role in the reliability and life of a gear coupling.

Poor lubrication between the gear teeth generates higher friction between these teeth, resulting in gear coupling wear, heat generation and high axial loads to mating equipment bearings. The higher axial loads on the bearings will then decrease the life of the equipment.

The pump shown on the left had a dry coupling that was operating in a torque-lock condition and creating high axial forces on the equipment. The coupling was replaced without making any adjustments to the pump or motor.

The only change was a coupling with good lubrication, which reduced tooth friction and decreased the axial forces from the coupling to the pump and motor. The result was a noticeable decrease in the operating temperature of the pump bearing.

Maintenance

Maintenance is the final factor to ensure gear coupling reliability for long equipment life. While the first three factors have more to do with a lack of knowledge, maintenance often comes down to a lack of execution.

Unfortunately, this requires discipline by operations and maintenance groups as well as managerial courage to dedicate the resources to ensure that it can happen.

Typical recommendations from gear coupling manufacturers require regreasing at a minimum of 12 months. A regreasing procedure would include breaking, cleaning, inspecting and hand-packing the coupling with fresh grease.

Using a grease gun typically is not recommended when the coupling has been broken and ready to receive new grease. When a gear coupling is greased through a fitting instead of hand-packing, it can result in overgreasing, and a hydraulic lock condition can occur, causing high axial forces on the equipment. A hydraulic lock condition can even make alignment difficult, as shafts may be hard to turn.

Some applications require regreasing at six months to ensure good reliability. These applications may include high speeds (high G forces), high temperatures, misalignment or vibration.

Smaller lube sump capacity can also be a factor in regreasing intervals. However, deciding to go longer than 12 months without grease replenishment on a gear coupling is a high-risk move that is not recommended.

Regular maintenance of gear couplings should involve special care with respect to many of the installation factors discussed previously. When inspecting gaskets and O-rings, ensure the lubricant stays in the coupling until the next maintenance task is scheduled. Grease fittings should be removed before completing maintenance.

These fittings have been known to leak lubricant and can hit guarding, causing loss of lubricant. Under high centrifugal forces, the grease must be completely sealed within the coupling. Guarding should also allow enough access so it does not have to be completely removed for normal coupling maintenance.

Remember, reliability is not for the faint of heart. Most all of these factors must be executed correctly to achieve good gear coupling reliability. This is why the work of maintenance and reliability professionals is rarely ever finished.

About the Author

Randy Riddell is a senior mechanical reliability engineer for International Paper in Courtland, Ala. He is a certified lubrication specialist (CLS) by the Society of Tribologists and Lubrication Engineers and a certified level I machinery lubrication technician (MLT) by the International Council for Machinery Lubrication (ICML). He is also a certified maintenance and reliability professional (CMRP) by the Society for Maintenance and Reliability Professionals (SMRP).