How to Design, Implement, and Manage an Effective Oil Analysis Program

Tags: oil analysis, lubrication programs, contamination control

How effective is your oil analysis program? To determine the answer, it is necessary to conduct a self-assessment of your program’s design and management. Many oil analysis programs have limited potential due to a lack of vision. This may be the result of insufficient training or not adequately understanding the capabilities of oil analysis.

Too often, the person responsible for the oil analysis program has simply accepted a program proposed by the lubricant vendor or a third-party laboratory, assuming that it will be suitable for the organization’s needs. While this assumption is not always wrong, the question becomes whether the program has been appropriately customized for the plant’s machine conditions, equipment criticality, and reliability objectives.

By learning how to perform a quick yet thorough self-assessment, a facility can evaluate the effectiveness of its current oil analysis program.

Program Assessment

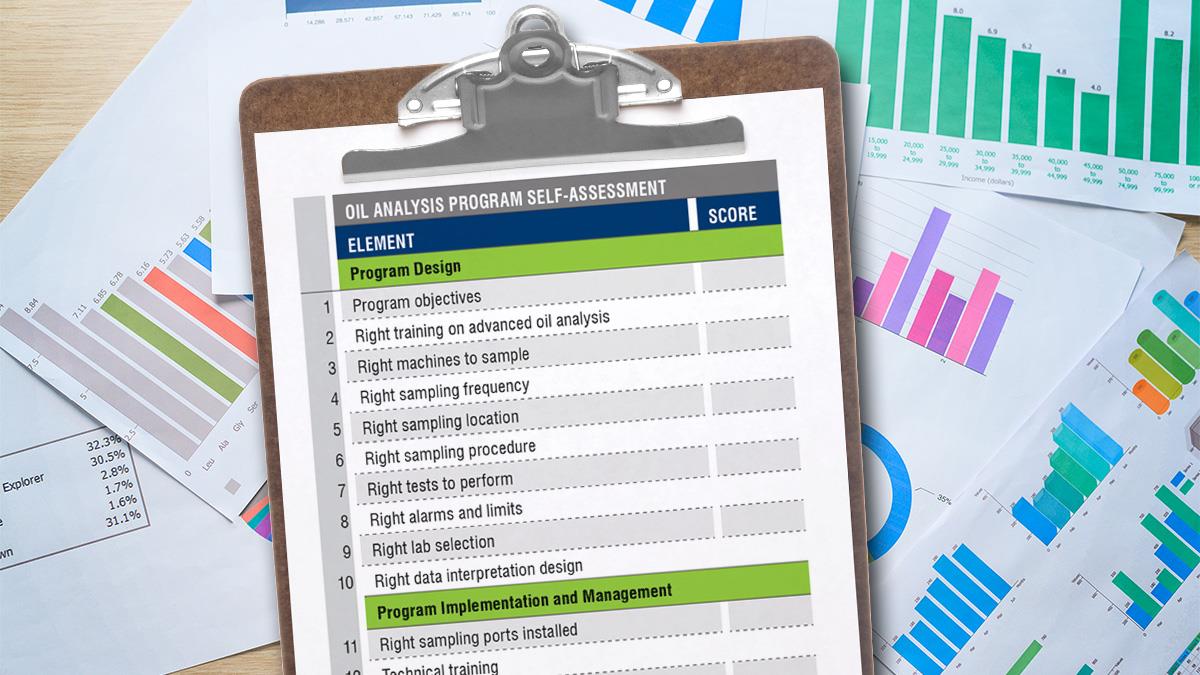

A self-assessment can be completed by scoring each of the 20 essential elements (shown above) on a scale from 1 to 4.

Score 1: A score of 1 would indicate that the element hasn’t been considered or there is no information on whether it has been included in the program design/implementation.

Score 2: A score of 2 should be recorded when there is little evidence that the element has been considered.

Score 3: A score of 3 signifies that appropriate documentation is available showing that the element has been considered for the program.

Score 4: A score of 4 would suggest that the element has been considered, discussed and documented for the program design/implementation.

Final Score: The final score is the sum of the 20 individual scores.

Self-Assessment Interpretation

Programs with scores of 80 and higher are working well but still may have a few areas that can be enhanced. An implementation plan that addresses specific issues can help you achieve greater reliability.

Programs that score between 50 and 79 have their strengths, but several aspects need to be corrected. Programs scoring 49 or below have a number of opportunities for improvement. Scores in this range indicate that you may be missing critical information from your machines.

Regardless of your current score, there is always room to improve. Through regular assessments, you can revitalize your oil analysis program and maximize its potential.

Program Design

The first step is to assess the design of your oil analysis program, including:

- Objectives

- Training

- Machine criticality

- Sampling frequency

- Test slates

- Sampling locations

- Alarms and limits

- Sampling procedures

- Lab selection

- Data interpretation

Establish whether the program has a holistic condition-based maintenance focus (predictive and proactive), or if it is designed to maximize oil change intervals. Is analyzing incoming oil part of the program? It is also essential to provide the appropriate training to the program manager so he or she can work with the laboratory to design and understand the program’s goals and features.

The machines included in the program should be based on their criticality, which is prioritized according to multiple factors, including:

- Costs

- Maintainability

- Safety

- Environmental risks or concerns

Sampling procedures must be performed correctly and consistently to expect representative oil samples. Sampling intervals should be set in relation to several parameters such as:

- Machine criticality

- Environment severity

- Oil age

- Machine age

Because oil contaminants vary in concentration at different points in a machine or lubrication system, it is critical to choose the best sampling locations. Once the sampling point is identified, it is usually necessary to install an appropriate sampling port.

Test slates should be chosen according to the program objectives and equipment criticality. Tests can be focused on analyzing lubricant health, contaminants, and wear debris, and can be classified as routine and exception tests.

Alarms and limits should alert you when a specific parameter is beyond normal conditions. They may be based on the original equipment manufacturer’s recommendations and historical information, but they should also be validated and adjusted to the specific machine’s characteristics.

The laboratory selection must also take into account:

- Technical capabilities (tests and experience)

- Quality assurance

- Information management

- Customer service

- Cost

Data interpretation should be generated based on the failure modes with highest probability and metallurgy of the machine. While there are typical failure modes for machines, a specific analysis should be conducted for critical machines according to their operating conditions.

Program Implementation and Management

Your program’s implementation and management should also be evaluated. These elements include:

- The sampling ports installed

- Training and skills management

- Sending samples to the lab

- The laboratory’s turnaround time

- Condition monitoring integration

- Results interpretation

- Proactive and corrective actions

- Continuous improvement

When implementing the program in the field, one of the first actions should be to install sampling ports in the correct locations with the necessary devices that allow taking a clean, reliable sample.

Training must be offered at different levels of the organization. Practical and procedural training should be required for technicians or operators who will take and label samples. Technical and interpretative training should be given to engineers or technicians who will interpret the information and confirm the actions to take. Managerial training should be provided to managers and supervisors responsible for the program’s implementation, execution, and continuous improvement.

Samples need to be sent to the laboratory within 24 hours after being obtained. The ideal laboratory turnaround time is 24 hours from the time the sample is received until the report is sent. Quickly sending samples to the lab, along with a short turnaround time, will be valuable in case there is an abnormal condition that requires prompt action.

The lab’s reporting software should have the ability to analyze trends for better detection of potential failures as well as access historical information for continuous feedback. Failure detection capabilities can be enhanced when two or more predictive technologies are combined, such as vibration analysis and oil analysis.

Appropriate interpretation should come from the data interpretation design, along with knowledge of the current operating conditions for the particular machine. When abnormal conditions are reported, specific actions must be taken. Simple actions may include filtering or changing the oil when it is contaminated, while more complex actions may involve investigating the root cause of the contamination to eliminate it.

Be sure the program is reviewed periodically or whenever there are changes to the plant’s machines, lubricants, oil analysis results, or reliability objectives.

This paper was provided as supporting materials for Alejandro Meza's speaking session at the Reliable Plant Conference. To learn more about attending Reliable Plant Conference, click here.