A Penny Pinched is Worth $1 Million Lost

Imagine you walk into the Dentist’s office, sit down in the chair and learn you have 5 cavities. You feel yourself sink in the chair at the thought of the dentist drill and the bill that is soon to follow.

It is in this same moment you replay the dentist’s advice offered on so many occasions: “All of this could have been avoided by daily flossing and brushing your teeth.”

Now imagine you are operating turbo machinery. It needs to be overhauled due to a bearing failure and at this same moment you replay this piece of advice: “The best way to deal with varnish is to never have to.”

At what point does the pain outweigh the decisions we make? How many cavities do you need before you embrace routine care of your teeth? How many hours of downtime do we need to experience before we embrace proactive maintenance?

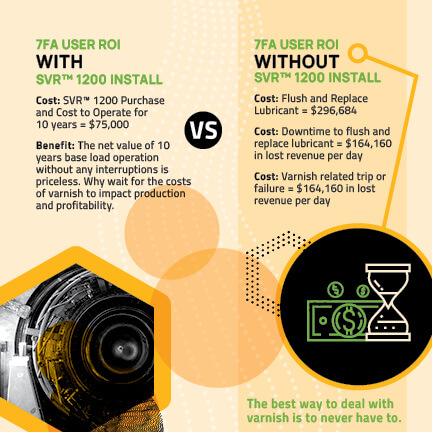

Let’s look a little deeper at the advice “The best way to deal with varnish, is to never have to.” Using the example of a 7FA Turbine, the below table paints a great picture of what a penny pinched in proactive maintenance adds up to in the end.

Does this shift your mindset of investing in proactive lubricant maintenance over the lifecycle of your turbine? An ROI of 3,498% is tough to ignore.

If we know the biggest gains and returns are experienced later, then budgetary considerations today can save you exponential costs in the long run.

When it comes to regular turbine maintenance and asset lifecycle management, it is all about the long game. Don’t wait for the costs of varnish to impact production and profitability. Be proactive and embrace solutions that protect your investment.

Start today. Save tomorrow.

For additional resources, visit www.cleanoil.com