Condition-Based Lubrication Using Ultrasound Technology

Tags: industrial lubricants

When it comes to proper bearing lubrication, what is your confidence level?

Determining both the frequency and quantity of lubrication are two perplexing issues facing technicians responsible for maintaining bearings. What happens if you use too much (or too little) grease on bearings?

Underlubrication can cause a bearing to wear out before its time, while applying too much lubrication often leads to catastrophic results for the bearing. It can even cause long-term damage to motor coils and windings.

With the help of ultrasonic tools and a little lubrication knowledge, technicians can make better greasing decisions or even automate the monitoring and greasing process.

The Current Mindset

Traditionally, lubrication scheduling has been time-based with equipment suppliers often recommending lubrication schedules set on criteria such as hours of operation. Suppliers frequently also provide instructions on the amount of lubricant to be applied during these scheduled maintenance procedures. It is not uncommon for clients to be told to lubricate at short-term intervals and to add what appears to be excessive amounts of grease. In one instance, a client was advised to lubricate motor bearings every two to three weeks and to add one ounce of grease. The origin of these suggestions leads one to speculate that they are often based on some unknown factors that have no real-world application.

A system of training, tools and planning that allows your staff to really “listen” to your bearings and understand exactly how to properly lubricate them could be invaluable in preventing early failures, unexpected production interruptions and other costs and issues related to under or overlubricated bearings.

Lubrication Intervals & Equipment Optimization

Lubrication intervals are based on a simple premise: keep equipment running optimally by preventing a bearing from running dry and causing catastrophic damage. While it is a solid preventive concept, a balance must be struck between preventing lubrication starvation and gross overlubrication.

To achieve equipment optimization, you need to know when to lubricate and when to stop applying lubricants to a bearing. How do you do this? By utilizing a condition-based lubrication strategy and letting the condition of the bearing determine when to lubricate. If a bearing is working properly and does not demonstrate any changes that warrant adding lubrication, the bearing should be left alone.

Should conditions change and a bearing demonstrate a need for lubrication, then a lubricant should be applied. Monitoring the bearing as the lubricant is applied will also help determine how much to add and when to stop the application.

Understanding Ultrasound Technology

Ultrasound technology is ideally suited for condition-based lubrication methods. To understand why, one must understand the ultrasound technology, how ultrasound is produced by bearings and how ultrasound-monitoring instruments can help maintain optimal lubrication levels in bearings.

Ultrasound technology is based on the sensing of high-frequency sounds. Ultrasound starts at 20,000 cycles per second, or 20 kilohertz (kHz). This is considered the high-frequency threshold at which human hearing stops. Most ultrasonic instruments will sense from 20 kHz up to 100 kHz. The range of human hearing covers frequencies from 20 cycles per second (20 Hz) up to 20 kHz. The average human will often hear up to 16.5 kHz and no more.

Ultrasound Instrumentation

Instruments based on the technology of airborne/structure-borne ultrasound are referred to as ultrasonic translators. These translators receive the inaudible high-frequency sounds and electronically translate them into the audible range through a process called heterodyning, which works in a similar fashion to an AM radio.

While we cannot hear radio waves, this method helps us easily identify different voices and musical instruments when we listen to the radio. Similarly, this heterodyning process provides an accurate translation of ultrasound produced by operating equipment and enables users to readily identify one sound component from another.

Most ultrasonic translators provide feedback in two ways: through headphones and on a meter where the amplitude of these sounds can be viewed as intensity increments or as decibels (dB).

Ultrasound Monitoring

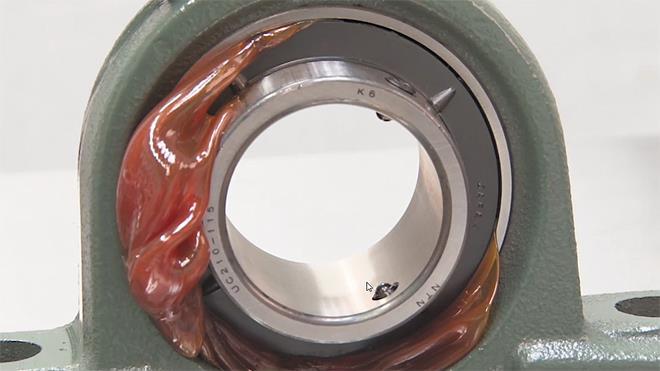

Imagine a properly installed bearing. It has been given the right amount of lubricant and is in perfect alignment. As it rolls around the raceway, any stress it may have is evened out by the lubricant, and it moves stress-free.

During this stress-free movement, it produces a recognizable rushing sound akin to the sound of air leaking out of a tire. This rushing sound is referred to as “white noise.” It includes all sounds, both low and high frequencies. The high-frequency waves generated by this white noise are more localized than those of the lower frequencies.

Using an ultrasonic translator, these signals can be detected with little or no interference from other mechanical noises generated by other components, such as a shaft or another bearing close by. (As opposed to vibration meters, which detect vibratory displacements of rolling elements, the ultrasound translator will detect friction.)

As the lubrication level in a bearing falls or deteriorates, the potential for friction increases. There will be a corresponding rise in the ultrasound amplitude level that can be noted and heard. The method to determine when to lubricate and when to stop applying lubrication with ultrasound instruments is as simple as setting a baseline, setting inspection schedules and monitoring during lubrication applications.

Setting a Baseline

A baseline for a bearing reflects the decibel level at normal operating conditions with no observable defects and with adequate lubrication. There are three methods for setting a baseline:

Comparison: When there is more than one bearing of the same type, load and rpm, multiple bearings can be compared. Each bearing is inspected at the same test point and angle. The decibel levels and sound quality are compared. If there are no substantial differences (less than eight dB), a baseline dB level is set for each bearing.

Set while lubricating: While lubrication is being applied, the technician can listen until the sound level drops and then begins to rise. At that point, no more lubricant is added, and the dB value is used as the baseline. Alternatively, in a system with continuous monitoring, the dB is trended allowing for quantitative measurement before and after lubrication.

Historical: Bearing dB levels are obtained from an initial survey and compared 30 days later. If there is little (less than eight dB) to no change in dB, then the baseline levels are set and will be used for comparison for subsequent inspections.

Setting Inspection Schedules

Equipment criticality, as it relates to production, environmental and operational consequences, is the primary factor in selecting and setting frequencies for assessing mechanical systems. After the baseline inspection has been performed, a monthly interval may sufficient. For bearings with high decibel levels that have been subsequently lubricated, frequent testing might be necessary to stay ahead of any possible changes. If a bearing is in a failure mode, the lubricant will temporarily mask the fault; however, the fault will quickly produce a rise in the dB level. In some instances, this will happen in minutes; in others, days.

However, if you are using a system that includes continuous monitoring, a set interval would not be required. Instead, the system can notify the user of the precise moment when lubrication is needed rather than waiting to catch the problem on the next scheduled test.

Monitoring as You Lubricate

A bearing that exceeds eight dB over a set baseline can be presumed to need lubrication. Once a bearing has been identified for lubrication, knowing when to stop applying the lubricant will prevent overlubrication. This is accomplished in one of three ways:

- Calculate the quantity based on the bearing manufacturers guidelines and apply that quantity of lubricant and no more. This has little dependence on ultrasonic methods, is subjective and often poorly executed.

- The lubrication technician monitors the bearing with an ultrasonic instrument as the lubricant is being applied. Lubricant is manually applied slowly until the decibel level drops to the baseline level. With a continuous monitoring system, regreasing can be activated remotely.

- If it is not possible to use a dB level as a guide, the lubricant is applied until the sound drops off and begins to rise. At that exact moment, the technician stops applying the lubricant.

Ultrasound Bearing Inspection

Ultrasonic inspection and monitoring is the most reliable method for detecting incipient (aka the very beginning of) bearing failure. The ultrasonic warning appears prior to a rise in temperature or an increase in low-frequency vibration levels. This method of inspecting bearings is useful in recognizing the beginning of fatigue failure, brinelling of bearing surfaces and an excess or lack of lubricant.

Detecting Signs of Failure

In ball bearings, as the metal in the raceway, roller or ball bearing begins to fatigue, a subtle deformation begins to occur. This condition will produce irregular surfaces, which will cause an increase in the emission of ultrasonic sound waves. A change in amplitude from the original reading is an indication of one of two conditions: pre-failure, or lack of lubrication, and incipient bearing failure.

An eight dB increase over baseline accompanied by a constant rushing noise suggests lubricant failure (dry bearing surfaces). When an ultrasonic reading exceeds any previous reading by 16 dB and is accompanied by crackling noises or an increase in the peak-to-peak value of a continuous dB reading, it can be assumed that the bearing has entered the beginning of the failure mode.

This information was originally discovered through experimentation performed by NASA on ball bearings. In tests performed while monitoring bearings at frequencies from 24 through 50 kHz, researchers found that the changes in amplitude indicated incipient failure before any other indicators including heat and vibration changes.

An ultrasonic system based on detection and analysis of modulations of bearing resonance frequencies provides subtle detection capabilities, whereas conventional methods are incapable of detecting slight faults.

As a ball passes over a pit or fault in the race surface, it produces an impact. A structural resonance of one of the bearing components vibrates or rings by this repetitive impact. The sound produced is heard as a qualitative change in the headphones, usually as a crackling sound, and observed as an increase in amplitude in the monitored ultrasonic frequencies of the bearing.

Lubrication Procedures

It is imperative to consider two elements of potential failure: lack of lubrication and overlubrication.

Normal bearing loads cause an elastic deformation of the elements in the contact area, providing a smooth elliptical distribution. But bearing surfaces are not perfectly smooth. For this reason, the actual stress distribution in the contact area will be affected by a random surface roughness. In the presence of a lubricant film on a bearing surface, there is a dampening effect on the stress distribution, and the acoustic energy produced will be low.

Should lubrication be reduced to a point where the stress distribution is no longer present, the normal rough spots will make contact with the face surfaces and increase the acoustic energy. These normal microscopic deformities will begin to produce wear and the possibilities of small fissures may develop, contributing to the pre-failure condition. So aside from normal wear, the fatigue or service life of a bearing is strongly influenced by the relative film thickness provided by an appropriate lubricant.

The appropriate amount of lubrication is critical. If a bearing is overlubricated, the bearing element or cage can be pushed (pressed) excessively by the lubricant, causing additional wear of the bearing. Too much lubricant causes churning and fluid friction. The heat from the fluid friction, coupled with the squeezing effect of churning, serves to drive the oil of the thickener prematurely; the oil dissipates through the seals and into the housing, and is lost.

On the other hand, if there is not enough lubricant, the bearing will rub on the solid surface, causing friction and wear on the bearings. Either case is detrimental to the life of the bearing, but using airborne/structure-borne ultrasound takes the guesswork out of lubrication.

Important Considerations

As with any technology, no one-size-fits-all application procedure exists. For example, there are some limitations of estimated regrease intervals/volumes using standard equations. One of the problems with time-interval lubrications is the different applications for different bearings, which varies among facilities.

A food-processing plant, for example, may use an application in which machinery is steamed down every day for cleaning. Another facility might not follow the same procedure if it operates in a different environment that does not require cleaning as frequently, and yet another might have many airborne particulates that could contaminate the bearing. Due to this amount of variability, one can only guess what the lubrication cycle should be. It depends on what a facility is producing and under what situations the machinery is operating.

Additionally, there are some considerations regarding where, when and how an ultrasonic approach can be used. If a facility approaches lubrication haphazardly, in a disorganized fashion or relies solely on sound quality as a determining factor, the effectiveness of the program can be compromised. One needs to track bearing condition over time, setting baseline levels and determining dB changes over that baseline to indicate the need to lubricate or not. Such a program helps personnel understand exactly what they are looking at.

Bearings that Are Difficult or Hazardous to Access

Bearings that are difficult or potentially unsafe to access can pose a challenge to properly lubricate by traditional methods. In applications like this, remote lubrication using ultrasonic feedback can offer an excellent solution for minimizing risk and reducing the number of difficult lubrication tasks. An integrated system allows for proper condition-based lubrication without the need to physically attend the bearing.

No matter what method you choose—ultrasonic listening tools or trending ultrasonic data continuously with an integrated system—ultrasound can play an important role in a successful condition-monitoring program.

Reference

1. NASA Tech Brief. Report B72-10494. August 1972.