In the dynamic pulp and paper industry, optimizing operational efficiency is paramount. Take, for example, two neighboring pulp and paper mills, part of the same organization, with a staggering 5,000 lubricated assets demanding daily complex and time-consuming lubrication attention.

LubePM, supported by Noria's Lubrication Program Development (LPD), was at the center of this ongoing effort to transform and revolutionize the lubrication practices at these two mills. This case study is a preview of their successes in progress.

Their current state showcases promising results as these mills undergo critical transitions, both with their onboarding training practices and constructing their lubrication routes through the LubePM lubrication management system.

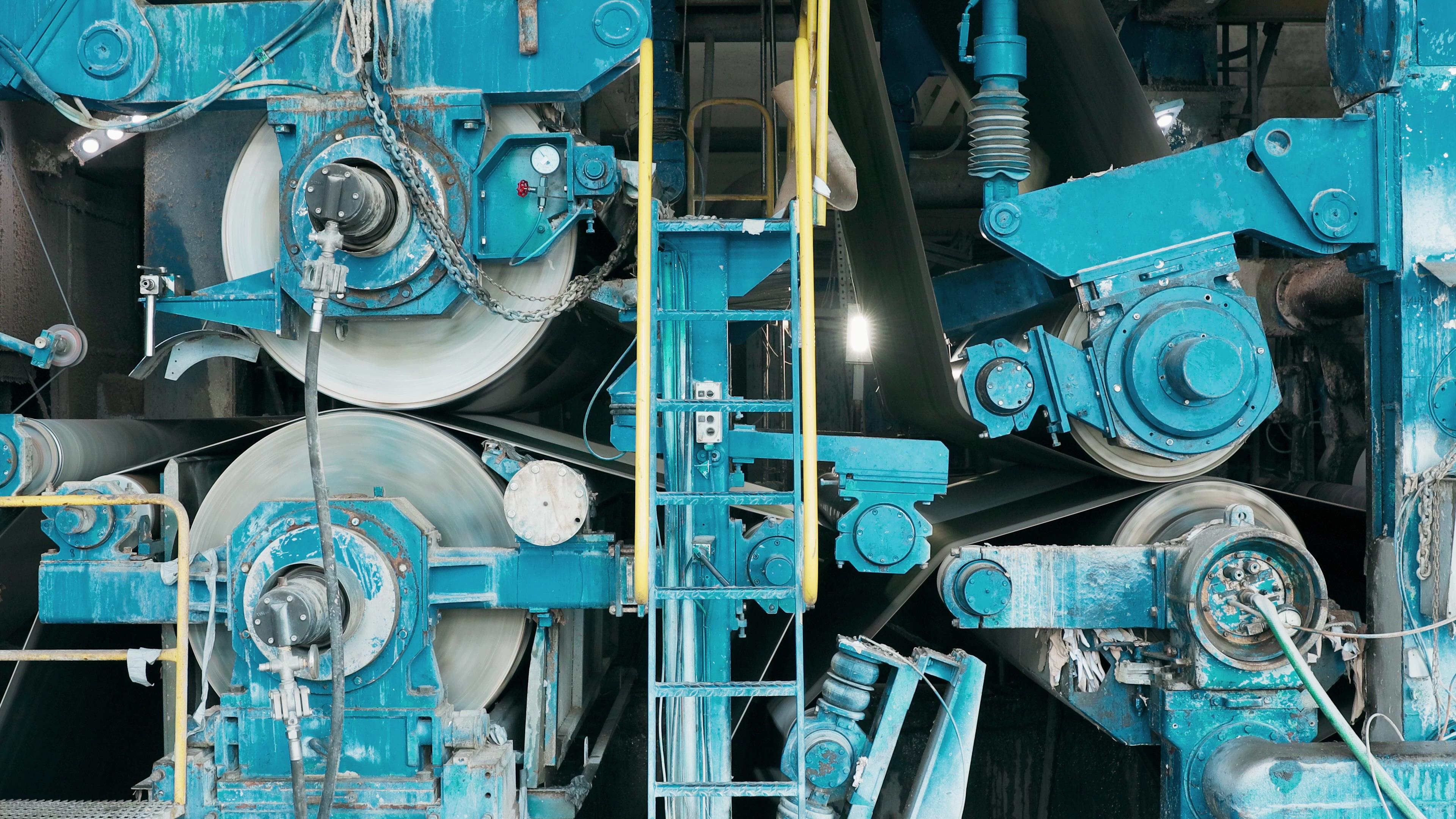

The two large pulp and paper mills are prominent players in their region. Their 5,000 critical lubricated assets require daily attention. Failure to perform these duties appropriately would harm their manufacturing operation, which is at the heart of a thriving industrial sector. Unfortunately, the mills faced significant hurdles caused by retirements, layoffs, and the economic impacts of the COVID-19 pandemic.

The mills' diverse range of lubricated assets, which required large volumes of oil and frequent relubrication, coupled with a volatile workforce, made maintaining consistent and effective lubrication practices a formidable challenge.

The departure of experienced personnel and the influx of new employees increased the risk of knowledge gaps and procedural errors. These factors led to frequent equipment failures, costly maintenance, and prolonged downtimes, threatening the mills' productivity and profitability.

Determined to transform their lubrication practices, the mills' management team enlisted the expertise of Noria Corporation, a renowned global leader in lubrication consulting and training services. Noria's LPD, a comprehensive program designed to enhance the reliability and performance of lubricated assets, emerged as the ideal solution for addressing the mills' challenges.

The maintenance and reliability individuals spearheading these initiatives at the mills became designated "lubrication champions." These champions collaborated closely with Noria's team of experienced consultants throughout their journey. The ongoing LPD implementation included:

- Lubrication Optimization: Noria's experts conducted an in-depth evaluation of the mills' lubrication processes, focusing on lubricant selection, application methods, and storage procedures. Based on their findings, they recommended optimized practices to minimize waste, improve lubricant effectiveness, and ensure consistent results across all lubricated assets.

- Comprehensive Training: Recognizing the importance of transferring knowledge, Noria conducted training programs tailored to the mills' maintenance personnel. These sessions covered essential topics like lubricant selection, handling, storage, and application. The goal was to equip the workforce with the necessary skills to execute lubrication tasks confidently and precisely.

- LubePM – Lubrication Management System: To streamline and organize lubrication activities, Noria introduced LubePM, an advanced lubrication management system to make lubrication tasks easier. This platform facilitates the creation of lubrication routes, enabling new personnel to learn from established best practices. Through LubePM, the mills gained the ability to effectively monitor maintenance schedules and lubricant performance, ensuring optimized lubrication practices across the facility.

While this case study remains an ongoing endeavor, the initial results of the pulp and paper mills' implementation of Noria's LPD and LubePM lubrication management system are promising. The mills are experiencing a transformative shift in their lubrication practices, with training programs empowering the workforce and implementing lubrication routes promoting consistency and knowledge sharing.

With the support of Noria's expertise, the mills aim to significantly reduce equipment failures, decrease maintenance costs, and enhance overall productivity. A comprehensive case study detailing the full extent of the mills' successful transformation and showcasing the remarkable outcomes achieved through Noria's LPD and LubePM will be released in the future.