Used oil analysis has long been a tried-and-true method for machine health condition monitoring. However, it does have its limitations. Therefore, embracing the inherent strengths of additional ancillary non-destructive testing (NDT) technologies provides a holistic approach and places your organization in a place to further succeed.

This isn’t an either-or type of consideration. Incorporating elements of each can strengthen the foundation of an end user’s current condition monitoring program, regardless of its current stage or level of sophistication.

Non-Destructive Testing

NDT is used to inspect and evaluate materials, components, or assemblies without destroying their serviceability while ensuring product reliability, controlling manufacturing processes, lowering production costs, and maintaining a uniform quality level.Source: ASNT

In this article, we’ll discuss the traditional concept of used oil analysis – the “why’s”, the “when’s”, and the “what can be improved upon” – compared to the status quo.

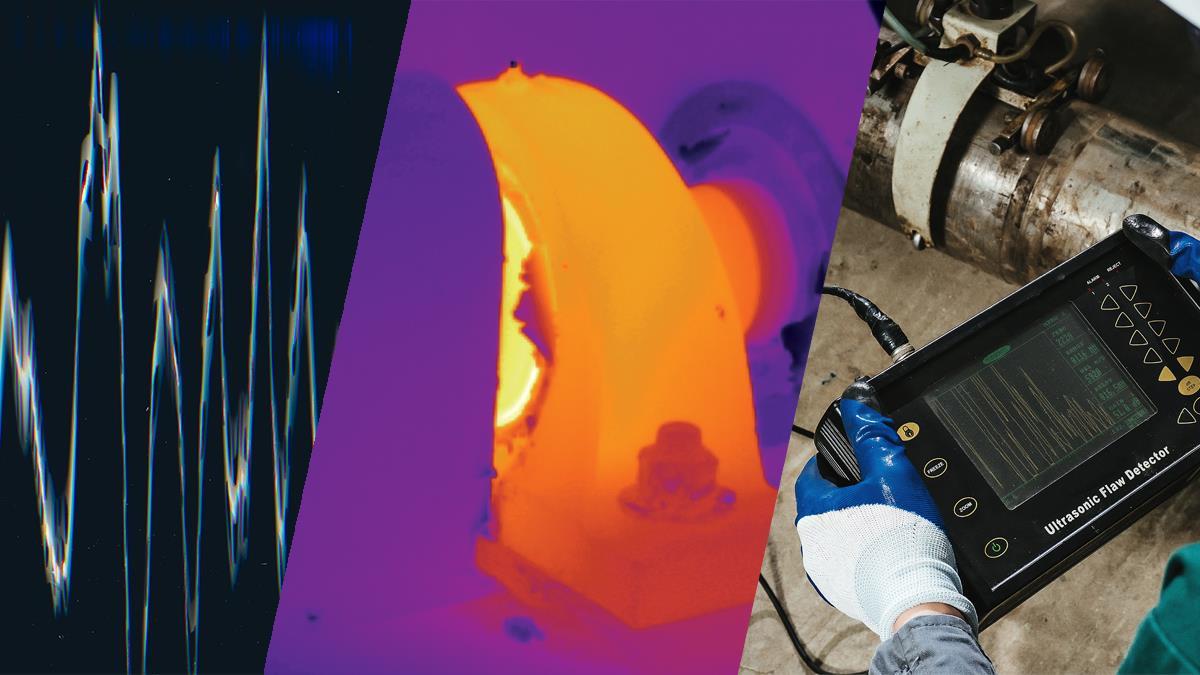

In addition, you’ll learn about three NDT technologies: vibration analysis, infrared (IR) thermography, and ultrasonics. We’ll discuss the various strengths and challenges with each, and most importantly, how these applications complement one another on your journey to operational excellence.

Traditional Used Oil Analysis

Regardless of the maintenance, reliability, or condition monitoring program you have, oil analysis is one of the oldest, most economical, and most effective technologies available, and it should be the base for your entire program.

In my three decades of experience, oil analysis has been the primary tool in my arsenal, allowing me to catch and diagnose impending failures with great success. As with any NDT, it requires end-user expertise; they must have intimate domain knowledge to extrapolate the data and provide insights that can lead to corrective actions and predictable outcomes.

Oil analysis accomplishes many things, but first and foremost, it determines the lubricant’s condition and identifies if it’s the right one for the application. Next, oil analysis can evaluate and determine the abnormal metallurgical wear and contamination captured in the oil and filter. This allows you to establish alarms, trends, and benchmarks that:

- Improve service intervals.

- Enhance corrective actions.

- Establish exemplary diagnostics.

- Create futuristic prognostics.

See Figure 1 for a basic overview of how to read a typical oil analysis report.

Unfortunately, it’s not uncommon to hear the phrase, “It’s just an oil analysis.” This thought process can cause challenges that impede the successful implementation of a used oil analysis program, including:

- Poor leadership commitment and communication.

- Failure to define what program success is, including program goals and key performance indicators (KPIs).

- Lack of implementation planning, including inadequate training and documentation of consistent processes and procedures.

- Deficiencies in database set-up and administration.

- Unacceptable sample turnaround times and failure to monitor and report issues.

- Failure to promptly act on data and results.

To anyone with this mentality – stop that thinking dead in its tracks, because it’s far more than that; it represents the lifeblood of the assets you are entrusted with. You should never neglect, downplay, or disregard testing protocols when managing your equipment’s health.

Putting effort into developing a solid routine with your used oil analysis program can have many benefits, including:

- Routine oil sampling.

- Integration with maintenance and reliability programs.

- Documented and standardized sampling practices and protocols (e.g., schedules and locations).

Performing routine oil analysis presents several advantages for your maintenance department, including:

- Improved planning and scheduling.

- Reduced unplanned maintenance activities.

- Support for your plant improvement initiatives.

- Reduced operating and capital costs.

- Improved equipment reliability and component life.

- Reduced replacement parts inventory and maintenance costs.

Vibration Analysis

Vibration analysis has been around for decades and is still one of the most effective ways to detect and quantify impending mechanical defects in rotating equipment. This helps to avoid catastrophic in-service failures and keep equipment reliability and production bottom lines as high as possible.

The primary causes of abnormal machine vibration include:

- Imbalance

- Misalignment

- Looseness

- Bearing deterioration

- Gear-related issues

Vibration data can be collected in a variety of ways, including hand-held data collectors, permanently mounted sensors or accelerometers, and even OEM factory-installed or in-field retrofit options. Data collectors measure the frequency, amplitude, direction, and acceleration of vibrations. Data is then sent to a software application to compile the information and provide the spectral plots, which can be analyzed for common identifiers.

Vibration monitoring is an effective tool that works in conjunction with routine oil analysis. In addition to the benefits of traditional used oil analysis, vibration analysis can:

- Assist in reducing equipment and labor costs.

- Help detect a single source of component failure months in advance.

- Predictably benchmark against similar components.

- Minimize unplanned maintenance and callouts.

- Assist in condition monitoring safety program optimization.

- Be highly effective at intermediate to high-speed component operations.

While a combined vibration and oil analysis program can provide tremendous benefits, vibration analysis does have some disadvantages such as:

- Relatively high cost for condition monitoring sensors, data collectors, and software.

- Requires additional space and equipment.

- Poor data collection if inadequate sensor type and installation locations are selected.

- Requires advanced training and testing certifications for technicians to be successful.

- A lack of skilled workforce availability may require you to outsource additional staff.

- The complexity of program setup.

Infrared Thermography

Infrared (IR) thermography uses an infrared imaging camera to detect and monitor infrared energy – or heat – that is invisible to the human eye. Every object that has a temperature above absolute zero will emit infrared electromagnetic energy that can be picked up by IR cameras.

IR thermography has numerous applications and is used in a variety of industries, including:

- Healthcare

- Military

- Firefighting

- Law enforcement

- Industrial machinery maintenance

An IR imaging camera is an extremely valuable diagnostic tool within an industrial plant. Since all machines or components will fluctuate in temperature before failure, the IR camera can detect these anomalies and alert that an issue is occurring.

In my experience, under or over-lubricated components will experience heat issues, and as we know, heat is a lubricant’s enemy. This alone makes it an excellent application in a facility.

Previously, I worked with mines and processing plants, and we frequently used IR thermography to capture thermal images of hydraulic cylinders’ temperature variance for bypass indications. Images of the radiator cooling systems’ hot spots were taken to find inefficiencies and plugged fins. We caught incidents of poor grease lubrication practices on bearing configurations and drive shafts more times than I can mention.

Thermography was also used to look for associated electric system faults with components such as high-voltage cables, connections, and transformers and to locate thermal leaks and overheated regions.

Some of the advantages of using IR thermography in maintenance are:

- It’s a no-contact, non-invasive method of monitoring machine conditions.

- No need to stop production from conducting the imaging of the machine or component.

- Data can be gathered on a large surface area in real-time.

- Software is available to complete a more detailed analysis of thermal images.

IR thermography provides real-time data, which can detect issues and trigger a used oil analysis. While this data can be highly valuable, the disadvantages of this technology include:

- The cost of infrared technology is high – not only the hardware (camera) but also software and labor costs.

- To be successful, a technician must have advanced training, the proper certifications, and a deep knowledge of the equipment.

Ultrasonics

When I think of applications for ultrasonics, my memory takes me to the joyful day when my wife and I could see the image of our first child months before he was born. Yes, healthcare is one of many areas in which ultrasound is utilized to improve our lives.

Ultrasound can also help to detect faults, deficiencies, cracks, and generalized failures and defects in equipment or component metallurgy. Ultrasound is especially helpful, for example, on weld inspections or structural integrity. Sound waves are introduced to the part being tested via a piezoelectric crystal transducer that converts electrical current to sound waves.

In my personal career, we utilized this technology to detect cracks in the steering systems of mining equipment, which if left undetected, could have led to equipment failures and the loss of human life. Similar to the other technologies, there are both advantages and disadvantages to be aware of.

Advantages of ultrasonics include:

- Relatively portable.

- Provides consistent, instant results.

- Capable of detecting surface and subsurface defects.

- Only requires limited access to machinery and components.

Disadvantages of this NDT technology include:

- Requires extensive training.

- Potentially difficult to operate on thin materials.

- The individual part geometry being tested can cause complications.

- Requires a relatively smooth surface to couple the transducer.

- The technician must know the velocity of the part and have a reference to calibrate against for equipment set-up.

In Summary

Having an array of technologies available allows a technician to bridge the gaps in analyzing the health of their industrial machinery and components. Traditional oil analysis and ancillary condition monitoring tools can arm them with technology and decision-making abilities to effectively identify, isolate, and remediate problems.

Technology alone does not solve every problem, rather it enhances the combined abilities, education, and experience of the brilliant men and women that lace up their boots and go work day after day in the trenches.

When used together throughout the life of your asset, these technologies can support your predictive and preventive maintenance programs and help to detect issues before they turn into catastrophic failures.