Headspace Management - Are You in On This Best-Kept Secret?

By now, most lubrication professionals are keenly aware of the reliability gains associated with contamination control. Those who have traveled down this road know that clean and dry lubricants often come at a price.

However, best practice may have nothing to do with removing contaminants or changing the oil. Actually, it may have nothing to do with the oil at all. Instead, it’s a practice of stabilizing the cleanliness and dryness in the headspace environment - the air above the oil in tanks, reservoirs and lubrication compartments.

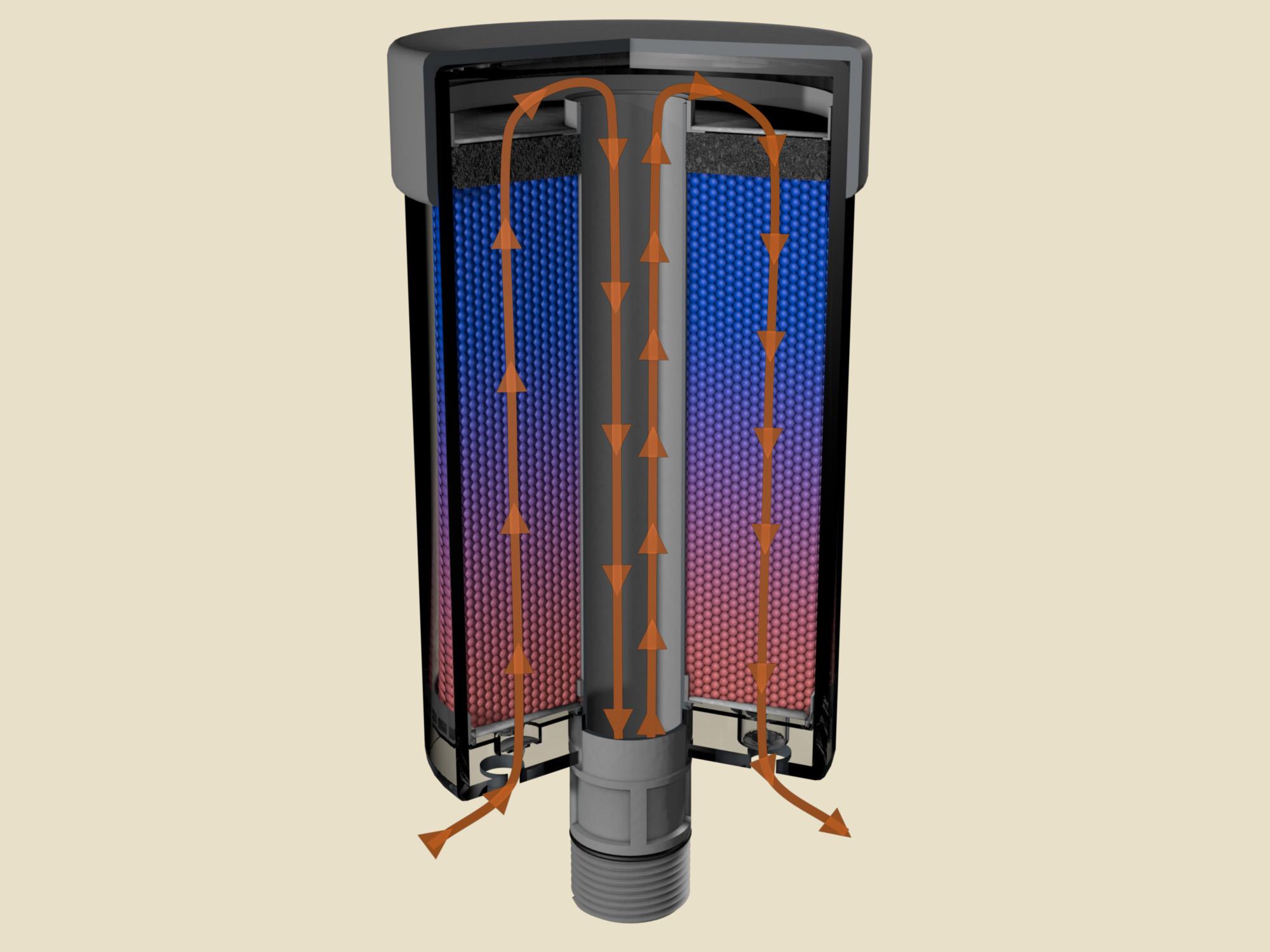

Why is this important? First, a high percentage of the particles and moisture that ingress into lubricating oils and hydraulic fluids must pass through the headspace. Therefore, the practice of excluding contaminants from entering the headspace, by default, excludes contaminants from entering the oil. This can be accomplished by channeling incoming ambient air through desiccant breathers that remove water and dirt.

Using options like check valves or a quick-exhaust manifold on desiccant breathers can also control the exchange of headspace air with ambient air.

The TTI SmartFlow™ adapter (available on Titan Power Breathers) is a quick-exhaust manifold that stops "exhaled" headspace air from contacting the desiccant media. Water removal is the second reason why stabilizing the headspace environment is important. With rare exception, a dry head space translates to dry oil - they go hand-in-hand. This is because wet is attracted to dry in the same way hot is attracted to cold.

Basically, a dry headspace forms a desiccant blanket above the oil and, like a sponge, draws water out of the oil. The lower the relative humidity of the air in the headspace, the faster and more efficient the process of mass transfer of water out of the oil becomes.

We all know that there are other contaminants besides water and dirt, such as air, sludge and heat. However, many lubrication professionals may be unaware of the impact dirt and water can have on the build-up of these other contaminants over time. For instance, when emulsified water is allowed to co-exist in the oil, a common consequence is entrained air. Emulsified water has a tendency to impair the quality of oil to rapidly release entrained air.

When air fails to detrain, a tertiary consequence is oil oxidation and adiabatic thermal failure, among others. Likewise, when dirt ingresses through tank headspace openings and enters the oil, this dirt abrades surfaces and leads to wear metals. This in turn accelerates the formation of oxide insolubles, leading to surface deposits and varnish. The list of secondary and tertiary consequences of dirt and water contamination is almost endless.

Therefore, when you ask the “repetitive why” in your search for the cause of oil or machine failure, you might find the root cause to be poor headspace management - now no longer a secret.

_extra_large.jpeg)

_small.jpeg)