5 Common Lubrication Problems and How to Fix Them

Tags: lubrication programs

One of the greatest opportunities I have as a technical consultant is the chance to walk through various plants around the world. I have visited power plants, food-processing plants, refineries, manufacturing facilities and a long list of others.

During these trips and audits, I have discovered several recurring lubrication issues that seem to be widespread throughout the industry. The following is a list of the most common problems and how they should be resolved.

1. Lack of a Labeling System

Labeling is a key part of any world-class lube program. Not only does it reduce the chance for cross-contamination by minimizing confusion as to which lubricants go where, it also allows individuals who may not be as familiar with the lube program to top-up with the correct oil or grease.

Anything that touches a lubricant

should be labeled and dedicated

to a single lubricant.

Of course, quality labels can be used for more than just identifying lubricants. On a recent project, the lube labels were barcoded to allow all assets in the plant to be integrated into the computerized maintenance management system (CMMS) for automatic work-order generation.

Although labeling assets is a great first step, a true world-class program would label everything from machines and top-up containers to bulk containers, grease guns and so on. Basically, anything that touches a lubricant should be labeled and dedicated to a single lubricant.

The Remedy

Developing a labeling scheme takes time, but when done properly, it can provide a variety of information not only about the lubricant but also about lubrication intervals as well.

The best label design incorporates a color/shape scheme for each lubricant used. This offers a quick visual reference as to which lubricant is inside the machine.

Noria has developed the Lubricant Identification System (LIS), which includes all basic information for a machine type such as base oil, application and viscosity. As mentioned previously, once a labeling system has been established, the labels should be applied to all lubricant storage containers and application devices.

2. Use of OEM Breathers and Dust Caps

Most original equipment manufacturer (OEM) accessories like breathers do little to restrict the ingression of tiny particles into oil and critical spaces, which can damage machine surfaces. Some of these breathers are simply a cap filled with steel wool or a mesh screen that serves as a block for larger particles.

Considering the lubricant film in a journal bearing is approximately 5 to 10 microns, any particles of this size contaminating the oil will greatly increase the likelihood of wear and subsequent machine failure.

These tolerance-sized particles do the greatest damage and have the highest probability of causing machine wear.

Most OEM breathers and dust

caps allow particles and moisture

to enter the oil.

Not only do many OEM breathers allow particles into the oil, they also do nothing to restrict moisture from entering the oil. Oil is hygroscopic, which means it absorbs moisture from the ambient air. In areas with high humidity or steam, moisture will pass through these types of breathers and be absorbed into the oil, causing rust, increased oxidation and hydrolysis rates, and a higher corrosive potential of acids formed by oxidation and hydrolysis.

The Remedy

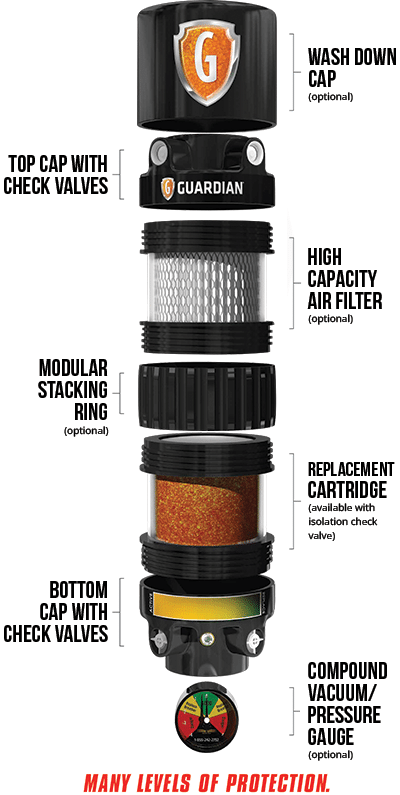

OEM breathers should be replaced with higher quality breathers to restrict particulate and moisture ingression. With several breather manufacturers on the market, the key is to get the breather that is right for your particular environment and operating conditions. In very dry environments, a spin-on particulate filter may work fine provided that ambient humidity is low. In more moist environments, a hybrid-style breather may be the best choice. This type of breather employs a particulate filter to trap hard particles followed by a desiccating phase to strip moisture from the incoming air. All of these breathers can be threaded into the current breather port for quick and easy installation.

GUARDIAN® breathers from Air Sentry offer add-on features so you can customize to your specific application requirements.

3. Lack of Procedures

Great lubrication programs are only as good as the people who do the work, just as a chain is only as strong as its weakest link. In many of my most recent projects, the retirement of technicians has been the problem of greatest concern.

As Baby Boomers are reaching retirement age and subsequently retiring, they are taking with them a great deal of personal experience and knowledge of how they do their jobs.

For some plants, the lube-tech position may have been held by a single person for decades. These professionals are the masters of their domains and know every sight, sound and smell of their machines.

It is imperative to pass down this type of dedication and understanding to the next generation of professionals. Unfortunately, all of this knowledge usually is not passed down. This results in problems and a steep learning curve.

Documented procedures can lessen the blow and help new personnel understand the proper way a task should be performed.

While countless articles and books have been published on the best way to write procedures, once written, the procedures must be implemented for their full effect to be realized.

The Remedy

Thorough documentation of every task performed in the lubrication program offers the best method for creating procedures.

You want to write a procedure not only for the application of lubricants (oil changes, regreasing, etc.) but also for how lubricants are handled in storage, decontaminated upon arrival and even disposed of after use.

Procedures should be developed with best practices in mind and may not represent what is currently being done in your plant. For instance, if new oil is arriving and being put into service without any testing or decontamination, this is far from best practice.

Instead, new oil should be sampled upon delivery to confirm its properties and tested for contaminants. If necessary, the new oil should be decontaminated before being released for service or put into bulk storage containers.

The same holds true for inspections, top-ups and every small task in the lubrication program. It is not enough to simply document what is currently being done. You must design procedures in a manner that enables the program to reach a world-class level.

Read more on how to create effective lubrication procedures:

Creating Best-practice Lubrication Procedures

Lube Procedures Are the Playbook for Lubrication Excellence

The Basics of Lubrication PM Procedures

Advantages of Documented Procedures for Lubrication Tasks

4. Improper Sampling Points and Hardware

If used correctly, oil analysis can be an extremely valuable tool. It allows you to monitor not only the health of the oil but also the health of the machine, as well as catch failures before they become catastrophic. In order to obtain all the benefits of oil analysis, you first must have the correct sample points and hardware.

Improper sampling points and hardware may result in samples that are full of historic data.

Many plants regard oil sampling as a secondary function and simply take samples from a drain port or with the inconsistent drop-tube method. When sampling from drain ports, you may obtain a sample that is full of historic data (e.g., layers of sediment and sludge).

Wear debris trends can also be hard to establish, as these samples often contain a high concentration of contaminants.

In addition to being inconsistent, drop-tube sampling frequently requires the machine to be taken out of service. This can result in particles settling at the bottom of the sump, which may prevent a good, relative sample being taken from the system.

Proper sampling ports can be achieved by modifying the machine. This will allow good samples to be taken consistently from “live” zones or areas inside the system where oil is experiencing turbulent flow.

The Remedy

All machines to be included in the oil analysis program should be evaluated for the proper sampling hardware. Splash-bathed components such as bearings and gearboxes can be equipped with minimess sampling valves with pilot tube extensions.

These extenders can be bent up into the “live” zone next to the bearing or gear teeth.

Circulating systems should be examined for the best possible sampling points as well. These systems typically require several points.

A primary point is where routine samples are drawn from to provide a snapshot of the entire system. The best place for a primary sample is on the main return-line manifold, before any return-line filters and in an area of turbulent flow (most often an elbow).

Secondary points should be installed in the oil return line after each lubricated component. Secondary points allow you to pinpoint problems in the system after an alarm has been triggered by the primary point.

In conjunction with sampling hardware installation, all technicians should be trained in the proper way to pull samples. All sample tubing should be flushed with five to 10 times the volume of dead space.

Great care should also be taken to reduce the amount of contamination introduced into the sample during the entire process.

5. Overgreasing

Most plants I visit do not recognize that grease guns are precision instruments. They also fail to see the problems that can be caused by the misuse of grease guns.

Just like many other people, I was taught to grease a bearing by simply attaching the grease gun and working the lever until grease was seen purging from somewhere.

While this may be effective for hinge pins and other applications where purging grease won’t cause damage, it shouldn’t be employed for all grease applications.

Overgreasing is a very common problem and can result in higher operating temperatures, premature bearing failure and an increased risk of contaminant ingression.

Overgreasing can result in higher operating temperatures, premature bearing

failure and an increased risk of contaminant ingression.

Bearings require a set volume of grease to be properly lubricated. A popular formula used to determine the volume of grease needed is the outside diameter (in inches) multiplied by the width (in inches) multiplied by 0.114.

This will provide the volume of grease in ounces that the bearing requires. Make your life easier and use our handy calculator for determining bearing grease volume and frequency.

Once you have calculated the volume of grease for the bearing, you need to know how much grease the grease gun is dispelling per stroke. To do this, simply pump 10 shots of grease onto a plate and weigh it on a digital scale. Next, divide the weight of the grease by 10.

This will give you the amount per stroke of output. Remember, certain grease guns can produce pressures up to 15,000 psi and can cause numerous problems if not properly managed.

The Remedy

While calculating the regrease requirements for all bearings onsite and determining the output of grease guns are a great place to start, there are other concerns that must be addressed as well. For instance, the output of grease can vary between guns.

The best way to counteract this problem is to standardize with a single type of grease gun so the output will be similar for each one. Grease guns should also be dedicated to a single type of grease and checked at least once a year.

If possible, bearings should be outfitted with grease purge fittings that allow excess grease to be expelled without compromising the integrity of the seal.

In addition, all professionals who operate a grease gun should be trained on their operation and the proper way to regrease a bearing.

3 Other Lubrication Problems to Avoid

Besides the top five problems, there are a few honorable mentions that should be included in any discussion of recurring lubrication issues affecting industry. These are problems that aren’t quite as common but still deserve to be mentioned.

Constant-level Oilers

Although constant-level oilers are great for providing small amounts of oil to a sump and replenishing lost oil, these devices require proper installation and maintenance. They should be installed on the appropriate side of the housing so the shaft rotation is toward the oiler.

This is more critical on smaller sumps. Also, the oiler must be installed straight, i.e., level and perpendicular to the ground. Finally, the oil level inside these devices should be set so half of the bearing’s bottom element is submerged in oil.

When using constant-level oilers, it is best practice to install a bull’s-eye sight glass on the opposite side of the housing from the oiler to ensure the proper oil level is maintained.

Sediment can block the piping and starve the bearing for oil. Air pressure can raise the oil level, causing increased drag and excess heat in the housing. With the oil sight glass in place, these issues can be recognized and corrected before any lasting damage is done.

High-speed Grease

Many facilities use a general-purpose grease for almost everything in the plant. However, a multi-purpose grease can cause problems in high-speed bearings.

Fan bearings, motor bearings and other bearings that rotate at several thousand revolutions per minute may require a grease with a lower viscosity than what is used for slower, more highly loaded bearings.

Most electric motors can be effectively lubricated by a grease with a base oil viscosity of 100 centistokes. If a higher viscosity grease is used, viscous drag can occur, which may result in higher operating temperatures and increased torque requirements to turn the bearings.

As the temperature increases, grease can drain from the bearing quicker, which in turn can cause the bearing to fail due to high heat or lack of lubricant.

To prevent this problem, assess all bearings and calculate the necessary operating viscosity. Next, select a grease that provides the required viscosity and the appropriate additive package for the application. You'll also want to take a look at Choosing a High-speed Grease.

One-dimensional Filter Carts

Filter carts offer many benefits, including increased lubricant life and reduced equipment failures. They are great tools for any lubrication program and should be used extensively to decontaminate both new and in-service lubricants. They can be employed to drain oil quickly, top-up with clean oil, flush out lines and hoses, etc.

Whenever I walk through a facility and see a filter cart not in use but sitting in the lube room, I think to myself, “what a waste.” These systems should never sit unused in a room somewhere.

The term “one-dimensional” refers to how these machines are often utilized. Many plants only use these carts to transfer oil from a drum to a reservoir, thus limiting their purpose. So avoid type-casting filter carts into a single role and use them for everything you possibly can.

While these are the most common lubrication problems across industry, there are many more. Some may be unique to certain processes or types of machines, but these five hold true for all facilities.

It’s been said that, “The problems are all the same; the only thing that changes is the accent.” Throughout industry, many people are facing the same challenges in their plants. The successes and lessons learned from these problems should be shared and disseminated to everyone.

As industry continues to change and evolve, it will become increasingly important to understand the problems being encountered and to look for new ways to solve them. By applying sound problem-solving techniques and searching for the low-hanging fruit, you can start to make lasting changes for the better. Take the next step. Learn how Noria can help transform your lubrication program.