Rolling-element bearings are found in everything from electric motors to gearboxes to conveyor systems. Basically, if a shaft needs to spin, it can be (and most of the time is) supported by a rolling-element bearing. However, the actual makeup of these devices can vary significantly based on the application. Use this field guide to understand different bearing types and applications.

Lubrication

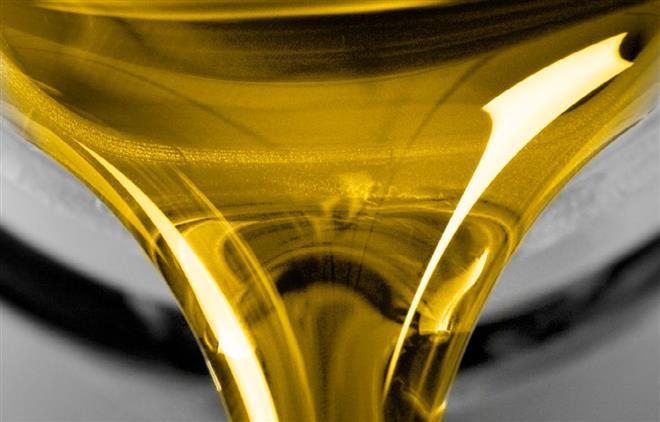

Proper lubrication is necessary for bearings to function correctly. Rolling elements undergo a lubrication regime known as elastohydrodynamic lubrication. In this regime, the thickness of the fluid film is usually less than one micron, and pressures can reach up to 500,000 pounds per square inch. When this happens, the oil momentarily turns into a solid and elastically deforms the rolling element and the mating surface. Any contamination can interfere with this process with devastating results.

To learn more about rolling-element bearings and their lubrication, read this article from a previous issue of Machinery Lubrication Magazine.