Investigations into the causes of breakdowns in hydraulic systems have shown that the majority of hydraulic-related failures can be attributed to high levels of solid contamination in the fluid. High levels of solid contamination are usually the result of inadequate filtration.

Effective filtration in hydraulic systems prevents breakdowns and increases the life expectancy of important and expensive components. The high cost of component repairs and system downtime can be kept to a minimum only through a preventive maintenance program that includes using and maintaining the proper system filtration. While price and delivery are important considerations, filter element performance should be the major deciding factor.

The constantly increasing demands made on hydraulic components means that today’s systems must be equipped with filters that have a high rate of particle removal efficiency at the required micron rating.

The correct number and type of filters required must be taken into account early in the system design phase. Likewise, the ability to change the filter on the run - often requiring the use of a duplex arrangement - is an important preinstallation consideration.

The good design intentions of the application design engineers are often overridden by the sometimes more powerful dictates of price and competition. System suppliers and purchasers often change the filter strategy by changing the filter size, micron rating and the number of filters.

This is an easy way to lower the overall system price. The equipment user may then have to add filtration to achieve the required system performance after the system is purchased, installed and operating.

ISO 16889:1999 Multi-pass Test

The purpose of the multi-pass test standard is to have a lab-based procedure that will provide reproducible test data that can be used to evaluate the dirt-holding capacity and the particulate removal efficiency (Beta Ratio) of a hydraulic fluid power filter element. The test measures the particulate removal efficiency as it relates to the ingression of dirt particles creating increased differential pressure over element life (Beta Stability).

Test dust of a known particle size distribution is added to the fluid in the injection reservoir until it reaches a specified concentration in grams of contaminant per liter of test fluid. The fluid in the injection reservoir is then pumped continuously into the clean fluid in the test reservoir, thereby creating a low concentration test solution. This test solution is circulated continuously to the test filter at a constant flow rate. The test solution is filtered by the element under test and travels back to the test reservoir (along with any unfiltered particles). This cleaned fluid is contaminated again by the injection fluid, and is once again pumped to the test filter.

During the test, the element differential pressure, the upstream and downstream particle counts and the amount of injected contaminant are continuously monitored. In most instances, the multi-pass test is completed when the element differential pressure reaches the specified limit or the Beta Ratios fall below a specified level.

Calculation of Beta Ratios

Beta Ratios for filter elements are determined during the multi-pass test as outlined above. The ISO 16889:1999 standard for multi-pass testing states that this test is applicable for filter elements that exhibit an average Beta Ratio greater than or equal to 75. Individual element manufacturers determine the Beta Ratio specification for their elements. Most manufacturers are currently using a minimum Beta Ratio of 200 for a particular micron rating.

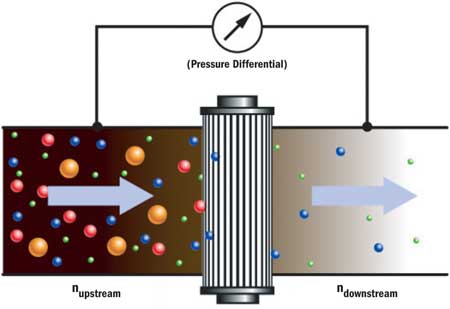

A single multi-pass test is divided into many smaller time segments. During each of these counting periods, the number of particles of a specific size - size x - and greater upstream of the filter is totaled and the number of size x and greater particles downstream of the filter is totaled.

The number of particles found upstream of the filter divided by the number of particles found downstream of the filter equals the beta value of the element at the given particle size during that counting period (Figure 2).

Figures 3 and 4 illustrate the beta values vs. the differential pressure across two filter elements at the end of each counting period throughout the entire test.

Figure 3. Element No. 1

Figure 4. Element No. 2

Calculation of Average Beta Ratios

To calculate the average Beta Ratio, the total test time taken to arrive at the element differential pressure alarm setting (or customer-specified value) is divided into 10 equal time frames. In each time frame, the sum (total number) of upstream particles from each counting period is calculated, then averaged. Accordingly, the downstream particles are summed and averaged. These values are then graphed against the differential pressure at the end of the time frame (Figures 3 and 4). This allows for the Beta Ratio to be determined at different differential pressures.

Calculation of a Single Beta Ratio for Length of Test

A single beta value for the duration of the test is derived by summing the average upstream particle counts from each of the 10 time frames, and dividing this total by the sum of the average downstream particle counts from each of the 10 time frames. These values are then used to determine the particle size that would yield the average beta ratio of 2, 10, 75, 100, 200 or 1,000.

Efficiency

Filter element efficiency for a particular micron rating is determined by the Beta Ratio for that micron rating. The calculation is Beta Ratio minus one divided by the Beta Ratio then multiplied by 100. For example, an element with a Beta Ratio of 200 for a particular micron rating has the following efficiency:

(200-1)/200 or

99.5 percent efficient

Table 1 shows the Beta Ratio, corresponding efficiency and the number of particles that will pass to the downstream side of the element for each 100,000 particles seen at the upstream side of the element.

Review of Sample Beta Ratio Curves

The two sample curves for filter elements shown in Figures 3 and 4 may be compared for a contaminant-sensitive servo valve application. Both filters have an average Beta Ratio equal to 300 for 3-micron particles. Judging by the average Beta Ratio, the elements would appear to have identical properties and no other Beta Ratio comparisons should be made.

However, as shown in Figure 3, the first element Beta Ratio is equal to b3 = 700 at the beginning of the test and slowly drops to a value of 200 at the end of the test. This element provides excellent contaminant protection in the beginning of the test and offers good protection at the end of the test.

The element could be used in all applications where a minimum beta value of 200 is necessary for the proper protection of the hydraulic equipment.

Surface Filtration

|

Depth Filtration

|

|

Figure 5. Absolute Filtration vs. Nominal Filtration

|

|

The second element (Figure 4) on the other hand, has a Beta Ratio equal to b3 = 50 at the beginning of the test and it slowly climbs to a maximum value of 700. Although the average Beta Ratio was equal to 300, the element may fail to protect the contamination-sensitive servo valve when first installed into the hydraulic system.

Only after dirt accumulates in the filter (and possibly after a system failure) does it provide the necessary system protection. Further examination of the beta curve for the element in Figure 3 shows that the Beta value remained at 200 or above well into the 20-bar differential pressure range. This shows that the element has very good Beta stability and will provide the necessary protection at all element differential pressures.

The Beta value for the second element, on the other hand, dropped rapidly to less than 75 after 8-bar element differential pressure. This element would not provide the necessary protection for the servo valves when the element differential pressure increased past 8 bar.

Beta Stability

Beta stability is the measure of how well a filter element is able to maintain its measured Beta Ratio at pressure drops beyond the limits of the normal operating range. For example, beta 200 stability = 210 psid, means that the Beta Ratio for the rated micron size will not drop below beta 200 until it reaches 210 psid across the element.

A comprehensive filtration strategy designed to maintain the proper target cleanliness for the system can substantially reduce contamination-related failures. Selecting filter elements for hydraulic and circulating systems is a serious undertaking because achieving and maintaining clean fluid begins with filter selection. Filter elements must be compared based on the multi-pass test results.

The Beta Ratio, or particle removal efficiency, is also a top selection criteria. Using elements with low Beta Ratios or poor efficiencies, even though the purchase price may be lower than an elements with high Beta Ratios or good efficiencies, will inevitably result in much more costly system failures.

References

- International Organization for Standardization (ISO). (1999). ISO Standard No. 16889:1999. Hydraulic fluid power filters - Multi-pass method for evaluating filtration performance of a filter element. Geneva, Switzerland.

- Principles and applications of hydraulic filters. HYDAC Filtertechnik.

- Scaglione, S. (1999). Summary of ISO 16889:1999. HYDAC Technology Corp.